Injection mold materials used in plastic injection factories must possess a range of properties, as the widespread use of plastic products relies on the support of precision molds. These molds operate in complex and variable environments, imposing strict requirements on the materials. Below are the key properties that plastic injection mold materials should have:

- Good High-Temperature Stability: Since molds often work in high-temperature environments, materials must have high temper resistance to maintain hardness and strength under heat, effectively resisting thermal softening and early wear, thus extending the mold’s lifespan.

- Excellent Thermal Fatigue Resistance: For molds subjected to frequent heating and cooling cycles, materials need strong thermal fatigue resistance to withstand the stress changes caused by these cycles, preventing surface cracking and peeling. This ensures dimensional accuracy and reduces the risk of mold failure due to thermal fatigue.

- Superior Corrosion Resistance: Given that plastic raw materials may contain corrosive elements like chlorine and fluorine, mold materials must offer excellent corrosion resistance. This protects the mold cavity surface from corrosive gases produced during heating, maintaining smoothness and precision, and ensuring long-term production stability.

- Strong Wear Resistance: During the injection molding process, the mold must endure the flow and sliding friction caused by the plastic deformation of the material inside the cavity. Therefore, the mold material must have excellent wear resistance. High hardness is a key factor in improving wear resistance. Additionally, the type, quantity, shape, size, and distribution of carbides in the material play an important role in determining the mold’s ability to resist wear and maintain precision.

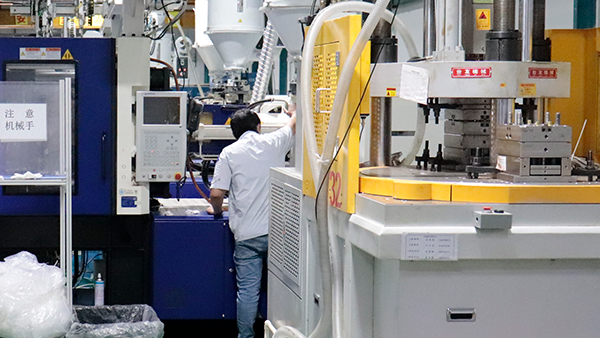

DAYIN Plastic Products Co., Ltd. specializes in manufacturing home appliance molds and offers OEM/ODM services. As a manufacturing solution provider, the company integrates R&D and production services. Its proprietary products include robotic vacuum cleaners, plastic tableware, and electronic dartboards. With 30 years of mold development experience, over 50 R&D personnel, and more than 100 injection molding machines, DAYIN is committed to providing high-quality manufacturing services and creating value for its customers.