In Vietnamese product injection molding, the design of the gating system is crucial. During the design process, molten plastic is typically fed upwards through the injection nozzle, forming a series of channels. These channels include the sprue and runner, which connect with gates and cold slug wells, directly impacting the molding quality of plastic products.

Sprue

In mold design, a channel is usually created within the nozzle or other cavity of the injection machine. This channel has an uneven shape to fit better with the nozzle. The inlet diameter should be slightly larger than the nozzle diameter to prevent material overflow or blockage, generally set between 4 and 8 millimeters. The sprue diameter should expand outward to facilitate demolding operations.

Cold Slug Well

In mold design, a cold slug well is positioned at the end of the sprue to capture any cold material from the nozzle. This design helps prevent blockage in the runners and gates. If cold material enters other cavities, it can cause internal stress in the product. The diameter of the cold slug well is usually kept between 8 and 10 millimeters, with a depth of around 6 millimeters. To facilitate demolding, the bottom of the cold slug well is designed with a zigzag or grooved shape, allowing easy removal of material from the sprue.

Runner

In mold processing, the design of runners is equally important. They are used to rapidly fill each cavity, typically distributed at symmetrical distances. The cross-sectional area and shape of the runners impact the flow of the molten plastic and the effectiveness of demolding. A circular cross-section design minimizes flow resistance, but cylindrical flow does not cool efficiently. Therefore, runners are generally placed between two parting planes, although this design is more complex.

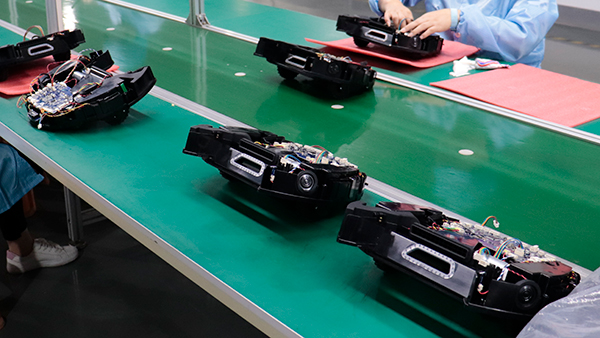

DAYIN Plastic Products Co., Ltd. specializes in home appliance mold manufacturing, offering OEM/ODM contract manufacturing services. As a supplier integrating R&D and manufacturing, DAYIN has 30 years of mold development experience, over 50 R&D personnel, and more than 100 injection molding machines, committed to providing high-quality manufacturing services that create greater value for clients. Our products include robotic vacuum cleaners, plastic tableware, and electronic dartboards.