The technology of plastic mold manufacturing is a comprehensive and complex process, involving aspects such as adhesive application, ejector pins, parting surface design and machining, process layout, and product appearance requirements. When handling mold design, the injection position and method need to be considered first. The use of adhesives is influenced by the number of cavities and product appearance, especially for large or complex-shaped products. The best practice is to select appropriate materials and create side or submarine gates to ensure optimal molding results.

When designing runners, the length and shape are crucial; a well-designed runner not only conserves material but also promotes smoother adhesive flow. Typically, the size of the primary runner should be 25% larger than the secondary runner. For products in high-appearance-demand fields, such as cosmetics, side gates should not be used long-term to avoid surface damage. In these cases, attention should be given to the use of adhesives and submarine gates.

Secondly, parting surface design is a critical step. When designing the parting surface, it is essential to check for undercuts to ensure the structure’s rationality, strength, and feasibility. Smooth parting surfaces and a minimized number of parting lines should be used to improve the mold’s performance and lifespan. After confirming all design elements, the core size of the mold can be determined. At this point, a 1:1 scale product view should be generated, with a mirrored copy applied based on the product’s shrinkage rate.

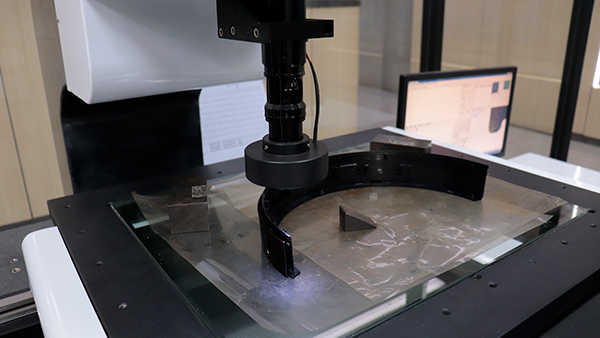

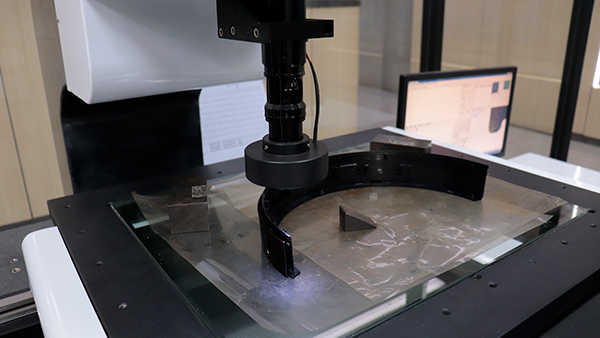

DAYIN Plastic Products Co., Ltd. specializes in the manufacturing of home appliance molds, offering OEM/ODM services as an integrated manufacturing solutions provider. Our main products include robotic vacuum cleaners, plastic tableware, and electronic dartboards. With 30 years of mold development experience, over 50 R&D personnel, and more than 100 injection molding machines, the company is committed to delivering high-quality manufacturing services to create greater value for our clients.