In the precision injection molding industry, each advancement comes with new challenges. This year, DAYIN Plastic Products Co., Ltd. has identified a significant issue facing the industry: the rising cost of injection molding. Below are some primary factors contributing to the increase in injection costs:

Increase in Labor Costs

In the Pearl River Delta region, rising labor costs have become a notable issue. Particularly in Shenzhen, the minimum wage has increased almost annually. Although the wages of injection technicians are generally above the minimum wage, employee salaries must be adjusted accordingly as the minimum wage rises. Additionally, the difficulty in recruiting workers has forced companies to revise their pay structures, resulting in a continual increase in labor costs, a common trend in the injection molding industry in recent years.

Rising Raw Material Prices

Due to the impact of oil price fluctuations on plastic production, the increase in raw material prices has directly led to higher injection molding costs. In the second half of 2016, the price of various materials rose across the board due to the increase in basic material costs, with some materials experiencing price hikes exceeding 20%. Although prices slightly decreased after the new year, overall costs remain higher than previous levels.

Increase in Auxiliary Material Costs

A wide variety of auxiliary materials are used in injection molding production, including paper, protective films, lubricants, and various mechanical components. The prices of these materials have also risen significantly, with paper and protective films seeing price increases of over 60%. Due to the relatively high labor demand associated with these materials, their prices have experienced notable growth, and other high-cost components have become common issues as well.

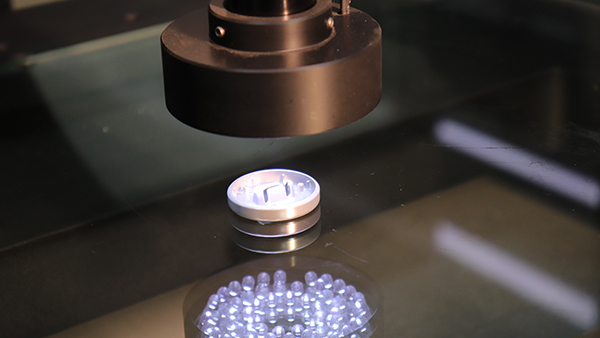

DAYIN Plastic Products Co., Ltd. specializes in home appliance mold manufacturing, providing OEM/ODM contract manufacturing services as a comprehensive solution provider integrating R&D and manufacturing. Our proprietary products include robotic vacuum cleaners, plastic tableware, and electronic dartboards. With 30 years of mold development experience, over 50 R&D personnel, and more than 100 injection molding machines, we are committed to delivering high-quality manufacturing services that create greater value for our clients.