Custom plastic product manufacturing factories handle a wide variety of plastic molds. Even molds of the same type differ in design and manufacturing due to variations in plastic materials, required molding precision, and assembly methods.

- Assembly Reference Points:

Assembly reference points can typically be divided into two categories: (1) using key working parts in the mold, such as the core, cavity, and inserts, as reference points for assembling other parts around these; and (2) using the side surfaces of guide pins, bushings, or mold base plates as reference surfaces for aligning and assembling components. - Injection Mold Assembly Precision:

The mutual precision between components is crucial and includes dimensional accuracy for distances, as well as requirements for concentricity, parallelism, and perpendicularity. Additionally, precision for relative movement (e.g., transmission, linear, and rotational accuracy), fit tolerance (e.g., clearances and interference fits), and contact accuracy (e.g., contact conditions) must be strictly controlled. The wall thickness of molded plastic parts should lean toward the lower limit of dimensions to ensure product quality. - Fitting Principles:

During fitting, the draft angle should ensure that the large end of the cavity is within the product’s dimensional tolerance, and the small end of the core also meets tolerance requirements. For corner radii, the cavity should be slightly smaller, while the core should be slightly larger. When molds feature both horizontal and vertical parting surfaces, ensure that when the vertical parting surface is in contact, the horizontal parting surface retains an appropriate gap. For small molds, a simple red-mark contact may suffice, while larger molds should maintain a gap of approximately 0.02 mm.

Therefore, before assembly, it is essential to carefully study and analyze the assembly drawings and part drawings to understand the function, characteristics, and technical requirements of each component. This helps in determining suitable assembly reference points. Through precise assembly, the final product can meet all quality standards and ensure the operational accuracy and technical requirements during the use of the injection mold.

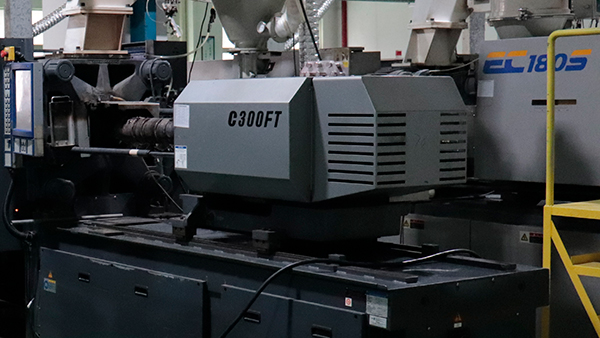

DAYIN Plastic Products Co., Ltd. has specialized in mold manufacturing for 30 years, providing one-stop OEM/ODM services as an injection molding contract manufacturer. The company excels in optimizing product structures to reduce mold and injection costs. With a comprehensive product design and manufacturing team, DAYIN offers high-quality product design services. Leveraging advanced mold processing equipment and extensive mold-making experience, DAYIN provides a full range of plastic product manufacturing services to clients. The company operates a 50,000-square-meter production facility, with 30 years of mold development experience, over 50 R&D personnel, and more than 100 injection molding machines.