With the rapid development of technology, the machinery industry is also advancing quickly, and the demand for injection molding production continues to increase. In the mold processing process, understanding how to efficiently complete tasks is crucial to ensure on-time delivery. DAYIN Plastic Products excels in mold processing, and the following is a brief overview of their production process.

First, since the actual conditions of each mold processing factory vary, the required processing methods and delivery times may differ as well. When selecting a mold processing manufacturer, understanding their production scale is important. It is recommended to choose larger manufacturers, as they generally have well-established management systems that ensure all stages are conducted in an orderly manner, reducing the risk of delivery delays and preventing disruptions in mold usage.

Secondly, it is equally important to choose a manufacturer with strong quality control capabilities. Such manufacturers will fully understand client requirements to ensure that the molds produced meet usage specifications and will reasonably set delivery times based on their production capacity. If the manufacturer is unable to meet the client’s specific requirements during production, they can communicate with the client and seek support from secondary producers. With the client’s approval, the manufacturer can adjust the production process to ensure timely completion of the order.

Lastly, to ensure that the molds are completed within the specified time frame, proper production scheduling is essential. When handling multiple orders, manufacturers should prioritize the production sequence according to delivery times, ensuring that each process is completed on time. For molds that require a longer production time, careful planning during scheduling is necessary to ensure timely completion of the production task.

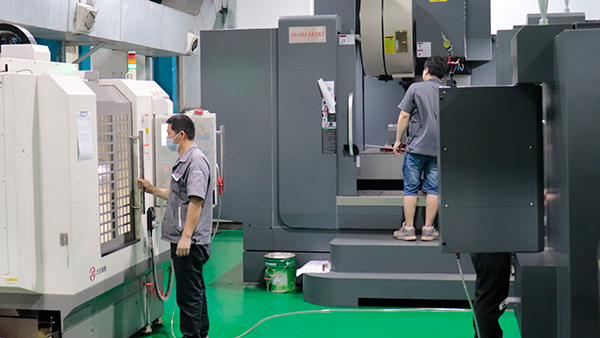

DAYIN Plastic Products Co., Ltd. has specialized in mold manufacturing for 30 years, providing one-stop OEM/ODM services as a contract injection molding manufacturer. The company excels in optimizing product structures to reduce mold and injection costs, with a full design and manufacturing team offering high-quality design services. With extensive experience in mold processing and advanced equipment, DAYIN Plastic Products Co., Ltd. provides manufacturing services for various plastic products, supported by a 50,000-square-meter production base, over 50 R&D personnel, and more than 100 injection molding machines.