Vietnamese injection molding companies use various types of molds in their production processes. To meet quality standards, the proper design and customization of molds are crucial. Mold creation involves turning designed molds into usable products through machining and manufacturing processes. Improving the efficiency and quality of mold making, while ensuring production demands are met, is a key goal for manufacturers. Here are several important considerations:

- Precision Machining and Manufacturing

Precision in mold machining and manufacturing is essential for ensuring mold quality and improving production efficiency. Advanced CNC equipment and processes significantly enhance mold precision and surface quality, reducing the need for additional polishing. During mold assembly, strict control of part dimensions and fitting accuracy ensures the quality and stability of the mold. - Proper Mold Usage

Proper mold usage is vital for extending mold life and boosting production efficiency. Molds should be installed and adjusted correctly to avoid damage from improper operation. Additionally, controlling mold usage frequency and production load helps prevent excessive wear. Regular maintenance, cleaning of mold surfaces, and lubrication of moving parts are necessary to effectively prolong mold lifespan.

- Continuous Improvement and Innovation

Mold making is a process of constant improvement and innovation. Manufacturing companies should actively adopt new technologies, processes, and materials to enhance their technical capabilities and innovation in mold making. Regular reviews of mold development and improvement help drive innovation in technology and processes. Staying informed about industry trends and market demands allows companies to adjust and optimize mold design and production workflows in a timely manner. Kaidi Molds places great emphasis on this, offering personalized customization services to its clients.

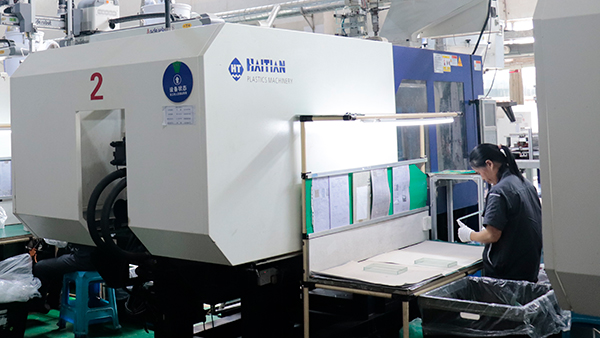

DAYIN Plastics Co., Ltd. focuses on home appliance mold manufacturing and offers OEM/ODM contract manufacturing services. As a comprehensive solution provider, the company’s product portfolio includes robotic vacuum cleaners, plastic tableware, and electronic dartboards. With 30 years of mold development experience, over 50 R&D staff, and more than 100 injection molding machines, DAYIN is committed to delivering high-quality manufacturing services that create greater value for its clients.