Injection molding by mold manufacturers is one of the key methods for material forming. Compared to mechanical processing, the injection molding process involves fewer steps, has higher material utilization, lower energy consumption, and is simple yet highly efficient. This has led to its widespread application across industries such as automotive, energy, machinery, electronics, information technology, and aerospace. Statistics show that 75% of rough-machined parts, 50% of industrial products, and 80% of household and electromechanical products require mold support after processing. As a result, the mold industry is often referred to as a “benefit amplifier,” driving growth in related sectors.

With the transformation and upgrading of industrial structures, the development trend of the mold and plastic products industry has gradually shifted towards high-end products, with increasingly comprehensive service functions. Although the growth rate of plastic product production has slowed, the market value remains substantial, and production continues to grow rapidly, indicating that the plastic processing industry is still on an upward trend.

As a metric for assessing the development of a country’s plastics industry, China’s technology ratio stands at only “0,” far below the global average of 50:50. In contrast, developed countries, such as Germany, have ratios of 63:37 or even 70:30. With technological advancements and consumption upgrades, China’s plastic products industry is expected to continue its steady growth. The mold industry, a fundamental sector of the national economy, spans numerous industries, including machinery, automotive, light industry, electronics, chemicals, metallurgy, and building materials. The rapid development of China’s industrial sectors, particularly in automotive manufacturing, IT manufacturing, and medical equipment, has created significant opportunities for the mold industry.

China is currently in a critical period of industrial restructuring, aiming to have the added value of strategic emerging industries account for approximately 15% of its GDP by 2025. To achieve this goal, high-end equipment manufacturing, as a future pillar industry, will drive national economic growth. As a core component of modern industry, the mold industry is set to benefit significantly from the robust development of high-end equipment manufacturing.

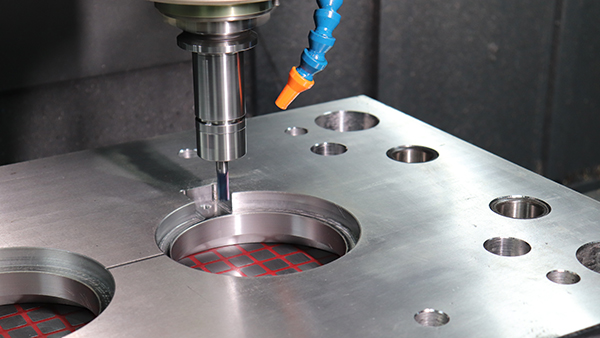

DAYIN Plastic Products Co., Ltd. is a high-tech enterprise specializing in product R&D, design, manufacturing, and sales services, providing one-stop solutions. Since its establishment in 1989, the company has focused on mold development, injection molding, post-processing, and electronic assembly. In addition to contract manufacturing services, we also develop our own products and support clients with private label production. With a 50,000-square-meter production base, 30 years of mold development experience, over 50 R&D personnel, and more than 100 injection molding machines, we are committed to delivering high-quality manufacturing services to our clients.