In China’s injection molding enterprises, various processing technologies are applied to customize injection plastic products for clients. When summarizing the processing technologies of plastic mold products, Vietnamese plastic mold manufacturers may offer different insights.

- Excessive pressure, high speed, excessive filling amount, over-injection, and prolonged holding time during processing can lead to excessive internal stress, resulting in cracking.

- Adjusting the mold opening speed and pressure is essential to prevent cracking during the rapid stretching of the workpiece.

- Low injection pressure or excessively high injection speed can also cause problems.

- It is important to prevent cracks caused by welding marks and to mitigate plasticity reduction due to plastic degradation.

- Proper use of release agents and regular cleaning of mold surfaces and other attached substances are necessary.

- Immediate annealing heat treatment after forming can effectively eliminate internal stress and reduce residual stress in the workpiece.

- Insufficient lubrication or poor lubrication effects can also impact product quality.

- Appropriately increasing the mold temperature facilitates the smooth release of parts, while lowering the material temperature can help prevent decomposition.

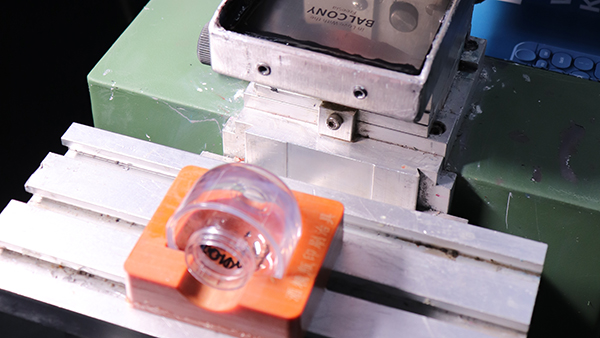

- During the production process, uneven cooling within the mold cavity, uneven plastic shrinkage, or unreasonable product structural design can easily lead to various defects.

- Poor plasticization, where the melt fails to achieve complete uniform melting, is also a common issue.

DAYIN Plastics Co., Ltd. specializes in manufacturing home appliance molds and provides OEM/ODM contract services. As a comprehensive manufacturing solution provider integrating R&D and manufacturing, our main products include robotic vacuum cleaners, plastic tableware, and electronic dartboards. With 30 years of mold development experience, over 50 R&D personnel, and more than 100 injection molding machines, we are dedicated to providing high-quality manufacturing services to our clients and creating greater value.