Injection Molding of Transparent Parts in Home Appliance Molds

Injection molding of transparent parts in home appliance molds presents significant challenges due to the high quality standards required. It is essential to avoid defects such as black spots, streaks, air bubbles, and discoloration. To achieve this, strict control is necessary during the design and molding process, including ensuring uniform wall thickness, sufficient draft angles, and smooth transitions at corners. Below are key considerations for injection molding of transparent plastic parts:

- Selecting the Right Plastic Material:

Choose plastic materials with appropriate characteristics and suitable for the intended environment, ensuring that the performance meets the product’s requirements. - Controlling Processing Temperature:

Adjust the processing temperature according to the selected plastic’s properties to avoid issues like melting deformation or hardening that could complicate the molding process. - Optimizing the Cooling Process:

Manage cooling speed to prevent deformation or cracking caused by internal stress. Proper control of mold temperature is crucial for maintaining product quality.

Maintaining a Clean Work Environment:

Ensure a clean processing environment to prevent contaminants from entering the plastic, which could affect the quality of the final product.

Conducting Quality Inspections:

After processing, perform a thorough quality inspection of the transparent plastic parts to ensure dimensional accuracy, appearance, and performance meet the required standards.

By following these precautions, you can effectively improve the quality of transparent part injection molding and reduce the difficulty of mold opening.

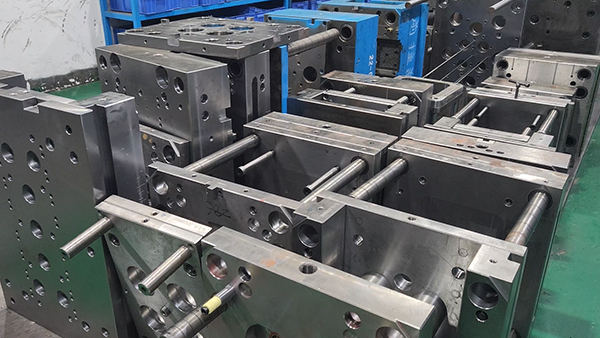

DAYIN Plastic Products Co., Ltd. has been specializing in mold manufacturing for 30 years. As a contract manufacturer providing injection molding and mold opening services, we offer comprehensive OEM/ODM solutions. We excel in optimizing product structures to reduce mold opening and injection molding costs. With a complete product design and manufacturing team, we provide excellent product design services. We have extensive mold processing equipment and years of mold-making experience, offering a wide range of plastic product manufacturing services to our clients. Our 50,000-square-meter production base, 30 years of mold development experience, over 50 R&D personnel, and more than 100 injection molding machines make us a leader in the industry.