In Vietnamese injection molding factories, plastic molds that are exposed to outdoor environments for extended periods are prone to aging issues such as fading, chalking, cracking, or spotting. Factors like temperature fluctuations, air humidity, and rainfall can affect plastic products to varying degrees. This is especially true in summer when strong sunlight and high temperatures accelerate mold aging. Therefore, Plastic Mold Co., Ltd. places great emphasis on preventive measures.

1. Importance of Sun Protection

Plastic Mold Co., Ltd. believes that the key to effective sun protection for plastic is the use of anti-aging agents, applied across different plastic products. Whether through coatings or other anti-aging materials, anti-aging agents are essential. When used properly, they provide effective sun protection, with particular benefits from various antioxidants.

2. Lightfast Colorants

In the production process of plastic molds, the durability of colorants is crucial. Ensuring that pigments have a high lightfastness rating can effectively address aging issues in materials. Typically, inorganic pigments perform better in terms of lightfastness than organic ones. However, certain organic pigment structures with better weather resistance are also worth considering.

3. Light Stabilizers

Light stabilizers are substances that can absorb or block ultraviolet (UV) rays, acting as a protective barrier for polymers. They absorb or reflect UV rays when light reaches the polymer’s surface, preventing UV rays from penetrating deep into the polymer. This effectively slows down the aging of the product. Various types of stabilizers are available to meet different needs.

4. Antioxidants

In the plastic industry, antioxidants are widely used. Choosing the right antioxidants can effectively capture free radicals and slow down the aging process, thereby extending the lifespan of plastic products and enhancing their value. There are many types of antioxidants available to suit various application requirements.

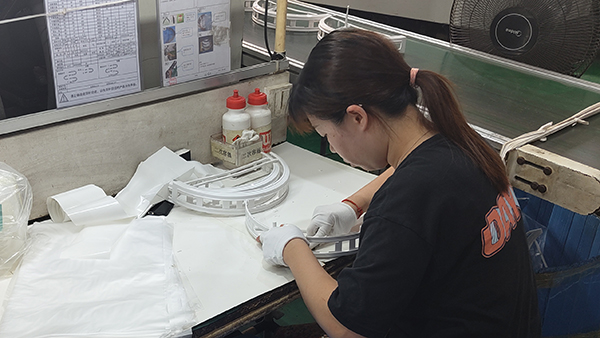

DAYIN Plastic Products Co., Ltd. is a high-tech enterprise specializing in product R&D, design, manufacturing, and sales, offering one-stop solutions. Since its establishment in 1989, the company has focused on mold making, injection molding, post-processing, and electronic assembly. With a 50,000 square meter production base, 30 years of mold development experience, over 50 R&D personnel, and more than 100 injection molding machines, DAYIN is committed to providing high-quality manufacturing services to its clients.