註塑成型, 作為現代製造中廣泛使用的塑性成型技術, is extensively applied in industries such as automotive, 電子產品, and medical equipment. Dimensional stability of products is crucial in injection molding, as it directly affects the quality and functionality of the final product.

1. Impact of Material Selection

Material Properties

Choosing the right plastic material is the first step in controlling dimensional stability. Different plastics vary in thermal expansion, flow characteristics, and shrinkage, all of which directly impact stability. Designers should select materials with good dimensional stability, such as polycarbonate (PC) or polypropylene (聚丙烯), while avoiding materials with high shrinkage.

Use of Additives

Additives like reinforcements, fillers, or stabilizers can enhance dimensional stability. 例如, glass fiber-reinforced plastics increase rigidity and strength, reducing deformation during molding. Heat stabilizers can lower thermal deformation during high-temperature molding, further enhancing stability.

2. Optimization of Process Parameters

Injection Temperature Control

Injection temperature significantly affects plastic flow and molding quality. Excessive temperature can degrade materials, while low temperatures may cause incomplete filling. Setting the injection temperature appropriately ensures smooth filling and minimizes dimensional deviations.

Holding Time and Pressure

Holding time and pressure directly affect filling and shrinkage. Extending holding time helps reduce shrinkage and improves stability. Adjusting holding pressure ensures that the plastic in the mold maintains pressure as it cools, reducing deformation risk.

Cooling Time and Temperature

The cooling process is essential for dimensional stability. Insufficient cooling may lead to incomplete solidification, affecting stability. Optimizing the mold cooling system and ensuring uniform cooling effectively minimize warping due to temperature differences.

3. Optimization of Mold Design

Mold Material and Precision

Mold materials and machining precision directly impact dimensional stability. Choosing wear-resistant, heat-stable steel for molds and maintaining precision within appropriate ranges ensures high product accuracy.

Thoughtful Parting Line Design

Placing parting lines away from critical product areas helps avoid dimensional instability. This also simplifies mold maintenance and improves production efficiency.

Cooling System Design

A well-designed cooling system considers the product’s shape and thickness, ensuring effective cooling and reducing temperature-related dimensional changes.

4. Production Environment Control

Temperature and Humidity Control

The production environment significantly impacts material performance. Maintaining optimal temperature and humidity (typically 20-25°C and 40-60% relative humidity) prevents material property changes that could affect dimensional stability.

Equipment Maintenance and Calibration

Regular maintenance and calibration of injection machines and equipment are essential for stable production. Routine checks ensure accurate parameters, avoiding dimensional deviations due to equipment issues.

Operator Training

Operator skills directly affect stability in injection molding. Training improves their understanding of process parameters and equipment, reducing operational errors and ensuring consistent production.

5. Quality Inspection and Control

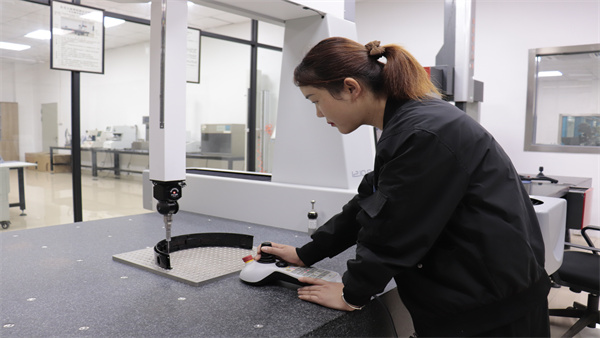

Online Detection Systems

Incorporating online detection systems enables real-time monitoring of product dimensional stability. High-precision measuring equipment identifies deviations, allowing for timely adjustments and waste reduction.

Sample Inspection

Periodic sampling and measurement during production help identify potential quality issues. Statistical analysis of inspection data highlights areas for improvement.

Feedback Mechanism

Establishing a robust feedback system ensures production issues are promptly reported to design and process teams, allowing for continuous optimization and improved stability.

6. Case Study

For a household appliance housing with strict dimensional stability requirements, the design team selected polypropylene (聚丙烯) with glass fiber reinforcement to improve rigidity. They optimized injection temperature and holding time through testing, chose high-precision steel for the mold, and implemented a uniform cooling system. Production was conducted under controlled temperature and humidity, with regular equipment maintenance. An online detection system and sampling inspection ensured consistent stability, resulting in a high-quality final product.

7. Future Trends

Application of Smart Manufacturing

With the growth of smart manufacturing, dimensional stability control in injection molding will become more precise. Data analytics and AI enable real-time monitoring and optimization, increasing automation.

Development of New Materials

Advances in materials science offer new options for stability. Future materials will provide designers with more stable, functional choices, meeting complex demands.

Introduction of Green Production Concepts

As sustainability becomes a priority, dimensional stability control will emphasize eco-friendliness. Future production will focus on recyclable materials and energy efficiency to reduce environmental impact.

Controlling dimensional stability in injection molding is essential for product quality. Through careful material selection, optimized process parameters, precise mold design, controlled production environments, and strict quality inspection, companies can significantly enhance dimensional stability. As technology and market needs evolve, dimensional stability control will bring new opportunities and challenges, revitalizing the industry.

If you’re struggling with dimensional stability issues in injection molding, DAYIN Plastics Products Co., Ltd. offers professional solutions. With advanced technology, extensive experience, and strict quality control, we ensure precision in your products. Contact us today!